Mastering SolidWorks: A Comprehensive Guide to Creating New Parts

Introduction: SolidWorks is a powerful computer-aided design (CAD) software used by engineers, designers, and manufacturers worldwide to create precise 3D models of mechanical parts, assemblies, and products. One of the fundamental tasks in SolidWorks is creating new parts, which serve as the building blocks for larger assemblies and designs. In this comprehensive guide, we will explore step-by-step instructions, tips, and best practices for creating new parts in SolidWorks, empowering users to unleash their creativity and design innovative components with ease and precision.

Understanding the Importance of Creating New Parts: Creating new parts in SolidWorks is the foundation of the design process, allowing users to conceptualize, model, and iterate on individual components before assembling them into larger structures. Whether you’re designing a simple mechanical component or a complex assembly, the ability to create new parts accurately and efficiently is essential for bringing your ideas to life in the virtual environment of SolidWorks.

Key Components of Creating New Parts: Before we dive into the process of creating new parts in SolidWorks, let’s familiarize ourselves with the key components involved:

- Sketching: Sketching serves as the primary method for creating the 2D profiles that form the basis of 3D parts in SolidWorks. Users can sketch lines, arcs, circles, rectangles, and other geometric shapes to define the geometry of the part.

- Features: Features are building blocks that add or remove material from the base sketch to create 3D geometry. Common features include extrusions, revolves, sweeps, lofts, cuts, fillets, chamfers, and more.

- Dimensions and Relations: Dimensions and relations define the size, shape, and position of sketch entities within the part. Users can add dimensions to control the size of sketch geometry and apply relations to maintain geometric constraints and relationships.

- Configurations: Configurations allow users to create multiple variations of a part within a single document. Each configuration can have its own set of dimensions, features, and properties, making it easy to explore different design options and variations.

Creating a New Part in SolidWorks: Now, let’s walk through the step-by-step process of creating a new part in SolidWorks:

Step 1: Open SolidWorks

- Launch SolidWorks software on your computer to start a new design session.

Step 2: Choose Part Template

- In the SolidWorks welcome screen, select the “Part” template from the available options. Alternatively, go to the “File” menu, choose “New,” and select “Part” from the templates list.

Step 3: Sketch the Base Feature

- Once the new part document is open, activate the “Sketch” tool from the Sketch tab on the Command Manager.

- Select the desired sketch plane (e.g., Front Plane, Top Plane, or Right Plane) to begin sketching.

- Use sketch tools such as Line, Rectangle, Circle, Arc, and others to create the 2D profile of the part.

- Apply dimensions and relations to define the size, shape, and position of sketch entities as needed.

Step 4: Create Features

- After sketching the base feature, exit the sketch environment by clicking on the “Exit Sketch” button.

- Activate the desired feature tool (e.g., Extrude, Revolve, Sweep, Loft, etc.) from the Features tab on the Command Manager.

- Select the sketch geometry to define the profile of the feature and specify the extrusion depth, angle, or other parameters as required.

- Click “OK” to create the feature and generate the 3D geometry of the part.

Step 5: Add Additional Features

- Continue adding additional features to the part using a combination of sketching and feature tools.

- Experiment with different feature types and techniques to achieve the desired shape, geometry, and functionality of the part.

- Use features such as Fillet, Chamfer, Hole, Cut, Rib, and Shell to refine and enhance the design as needed.

Step 6: Review and Validate

- Once the part geometry is complete, review the design to ensure accuracy, completeness, and compliance with design requirements.

- Use SolidWorks tools such as Measure, Mass Properties, and Section View to analyze the part geometry, dimensions, and properties.

- Make any necessary adjustments or modifications to refine the design before proceeding further.

Step 7: Save the Part

- Save the new part document to a location on your computer or network using a descriptive filename that reflects the part’s identity or purpose.

- Choose the appropriate file format (e.g., SolidWorks Part (*.sldprt)) and version compatibility options as needed.

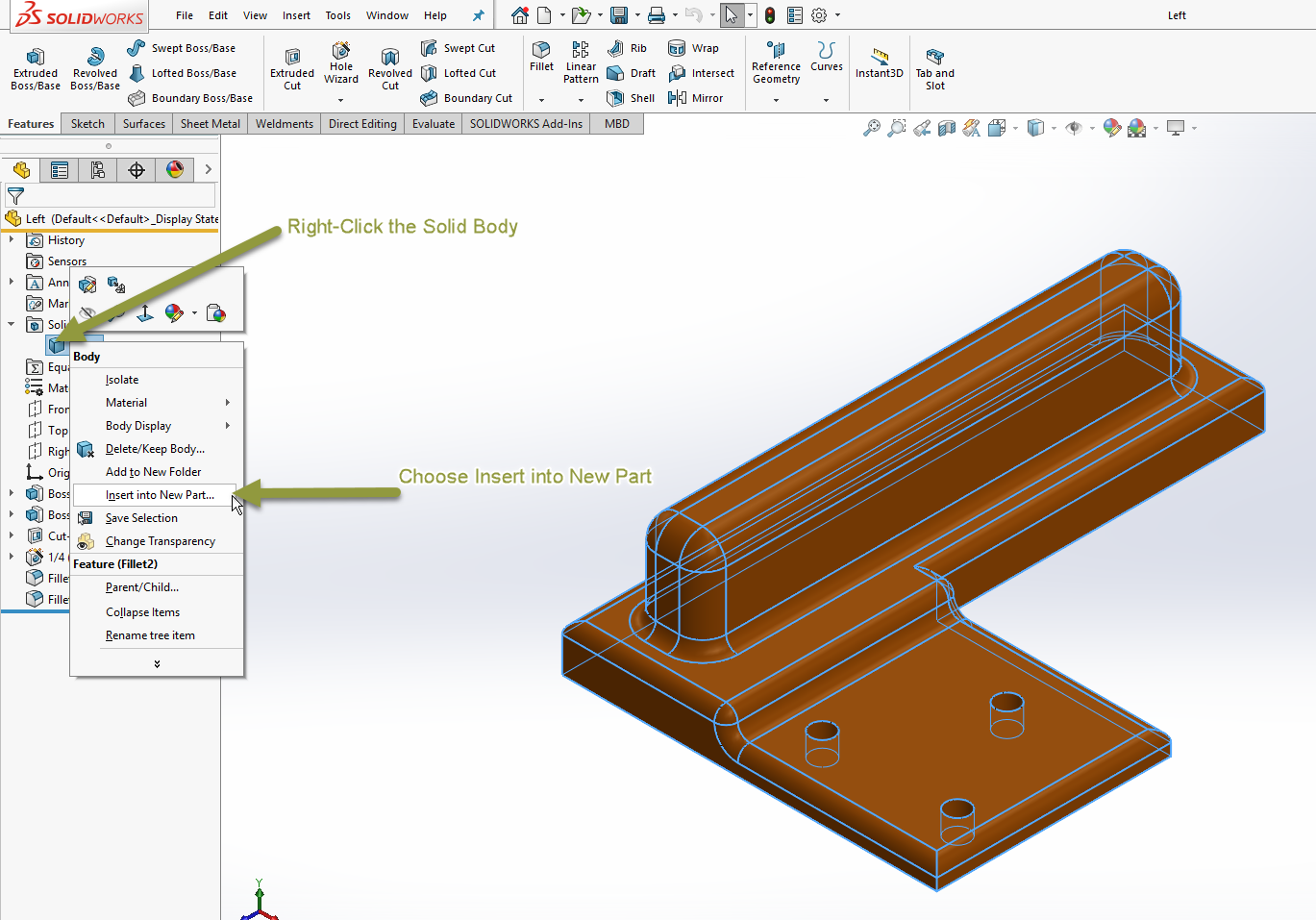

Advanced Techniques for Creating Parts: In addition to the basic steps outlined above, SolidWorks offers several advanced techniques and features for creating complex and innovative parts. Here are some advanced techniques you can explore:

- Parametric Modeling: Utilize parametric modeling techniques to create parts with dimensions and features that are driven by mathematical equations, formulas, or design parameters. Parametric modeling allows for flexible and adaptive designs that can be easily modified and updated.

- Design Tables and Equations: Use design tables and equations to automate the creation and configuration of parts with multiple variations. Design tables allow you to specify different dimensions, features, and properties for each configuration, while equations enable you to define relationships and constraints between dimensions and parameters.

- Top-Down Design: Adopt a top-down design approach to create parts within the context of larger assemblies. Start by defining the overall assembly structure and relationships, then create individual parts that fit within the assembly constraints and requirements.

- Surface Modeling: Explore surface modeling techniques to create complex and organic shapes that cannot be easily achieved with traditional solid modeling methods. Use tools such as Boundary Surface, Lofted Surface, and Freeform to create smooth and contoured surfaces.

Best Practices for Creating Parts: To create efficient, reliable, and manufacturable parts in SolidWorks, consider the following best practices:

- Plan Before You Sketch: Before starting a new part, take the time to plan out the design concept, requirements, and constraints. Consider factors such as functionality, manufacturability, assembly, and performance to guide your design decisions.

- Keep Sketches Simple and Clean: Maintain clean and well-organized sketches by using minimal geometry, avoiding redundant or unnecessary entities, and applying geometric constraints and dimensions effectively.

- Design for Manufacturing: Design parts with manufacturability in mind, considering factors such as material selection, machining processes, tolerances, and cost implications. Optimize part geometry to minimize machining operations, reduce material waste, and improve production efficiency.

- Use Standard Components and Features: Whenever possible, utilize standard components, features, and design practices to streamline the design process and ensure compatibility with existing systems, assemblies, and workflows.

Conclusion: Creating new parts in SolidWorks is a fundamental skill that empowers users to design, innovate, and bring their ideas to life in the virtual world of CAD. By following the step-by-step instructions, tips, and best practices outlined in this guide, you can create precise, functional, and visually appealing parts that meet the needs of your projects and applications. Whether you’re a beginner or an experienced user, mastering the art of creating parts in SolidWorks opens up a world of possibilities for creativity, exploration, and engineering excellence. So next time you embark on a new design project, remember the principles and techniques shared in this guide to create parts that stand out and make an impact in the world of CAD and engineering.