Mastering Mechatronic System Modeling and Simulation in LabVIEW: A Comprehensive Guide

Introduction: Mechatronic systems, integrating mechanical, electrical, and software components, are ubiquitous in modern engineering applications, from robotics and automation to automotive and aerospace systems. LabVIEW, a powerful graphical programming environment developed by National Instruments, provides a versatile platform for modeling, simulating, and controlling mechatronic systems. In this comprehensive guide, we will delve into the intricacies of modeling and simulating mechatronic systems in LabVIEW, covering everything from system design and component integration to simulation setup and real-time control.

Section 1: Introduction to Mechatronic System Modeling 1.1 Overview of Mechatronic Systems: Mechatronic systems combine mechanical, electrical, and software components to achieve desired functionality and performance. These systems often involve complex interactions between physical elements, sensors, actuators, and control algorithms. Modeling and simulating mechatronic systems enable engineers to analyze system behavior, optimize design parameters, and validate control strategies before implementation.

1.2 Importance of Mechatronic System Modeling: Modeling and simulation play a crucial role in mechatronic system design and development, offering several benefits:

- Predictive Analysis: Models allow engineers to predict system responses under different operating conditions, facilitating design optimization and performance evaluation.

- Design Validation: Simulation enables engineers to validate control algorithms, assess system stability, and identify potential issues early in the design process.

- Cost and Time Savings: By simulating mechatronic systems, engineers can reduce the need for physical prototypes, minimize testing costs, and accelerate time-to-market for new products and technologies.

Section 2: LabVIEW Fundamentals for Mechatronic System Modeling 2.1 Introduction to LabVIEW: LabVIEW is a graphical programming environment widely used for data acquisition, instrument control, and system automation. LabVIEW features a visual programming language called G (Graphical Programming Language) that allows users to create custom applications and virtual instruments (VIs) by connecting graphical icons, or nodes, in a block diagram.

2.2 LabVIEW Components for Mechatronic Modeling: LabVIEW provides a rich set of tools and libraries for modeling and simulating mechatronic systems, including:

- Simulation Modules: LabVIEW offers simulation modules, such as the System Identification Toolkit and Control Design and Simulation Module, for modeling dynamic systems, identifying system parameters, and designing control algorithms.

- Signal Processing Libraries: LabVIEW includes signal processing functions and libraries for analyzing sensor data, filtering signals, and implementing control algorithms.

- Hardware Integration: LabVIEW seamlessly integrates with hardware platforms, such as NI DAQ (Data Acquisition) devices and CompactRIO controllers, for real-time data acquisition, control, and simulation.

Section 3: Modeling Mechanical Components in LabVIEW 3.1 Mechanical System Representation: Mechanical components, such as motors, gears, and linkages, can be represented using mathematical models based on physical principles and equations of motion. In LabVIEW, engineers can create mathematical models of mechanical systems using block diagrams, state-space representations, or custom mathematical functions.

3.2 Dynamic System Modeling: LabVIEW provides tools for modeling dynamic mechanical systems, including:

- Transfer Function Models: Engineers can use transfer function models to represent linear, time-invariant (LTI) systems, such as springs, dampers, and mechanical resonators.

- State-Space Models: State-space models are used to represent complex dynamic systems with multiple inputs and outputs, allowing engineers to analyze system behavior in both time and frequency domains.

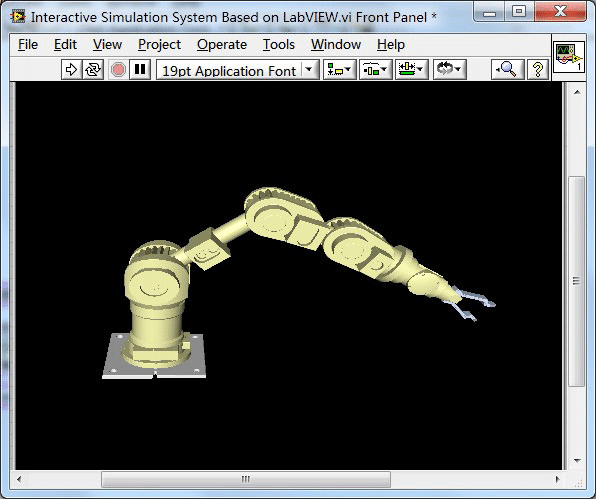

- Multibody Dynamics Simulation: LabVIEW offers simulation tools for modeling multibody dynamics systems, such as robots and mechanisms, using rigid body dynamics and kinematic constraints.

Section 4: Modeling Electrical and Electronic Components in LabVIEW 4.1 Electrical System Representation: Electrical components, including sensors, actuators, and circuits, can be modeled using electrical circuit analysis techniques and component models. In LabVIEW, engineers can create circuit diagrams, simulate electrical circuits, and analyze circuit behavior using built-in simulation tools and libraries.

4.2 Electronic System Simulation: LabVIEW provides tools for simulating electronic systems and circuits, including:

- Circuit Simulation: Engineers can simulate analog and digital circuits using SPICE (Simulation Program with Integrated Circuit Emphasis) simulation engines, allowing them to analyze circuit performance, verify design specifications, and troubleshoot circuit behavior.

- Power Electronics Simulation: LabVIEW offers simulation modules for modeling power electronics systems, such as inverters, converters, and motor drives, enabling engineers to design and optimize power electronic circuits for efficiency and performance.

Section 5: Integrating Mechanical and Electrical Models in LabVIEW 5.1 System Integration: Mechanical and electrical models can be integrated in LabVIEW to create comprehensive mechatronic system models. Engineers can combine mechanical dynamics, electrical circuits, and control algorithms in a unified simulation environment, allowing them to analyze system interactions, design feedback control loops, and optimize system performance.

5.2 Co-Simulation: LabVIEW supports co-simulation techniques, allowing engineers to interface with external simulation tools, such as MATLAB/Simulink or SolidWorks, for modeling specific components or subsystems. Co-simulation enables engineers to leverage the strengths of different simulation tools and integrate multidisciplinary models into a cohesive simulation environment.

Section 6: Simulating and Analyzing Mechatronic Systems in LabVIEW 6.1 Simulation Setup: To simulate mechatronic systems in LabVIEW, engineers define system parameters, initial conditions, and simulation settings using block diagrams or graphical user interfaces (GUIs). LabVIEW provides simulation tools for running simulations, analyzing simulation results, and visualizing system behavior in real-time or offline.

6.2 Data Analysis and Visualization: After running simulations, engineers analyze simulation results using LabVIEW’s data analysis and visualization tools. Engineers can plot time-domain and frequency-domain responses, generate simulation reports, and perform statistical analysis to quantify system performance, validate design specifications, and identify optimization opportunities.

Section 7: Real-Time Control and Hardware-in-the-Loop (HIL) Simulation 7.1 Real-Time Control: LabVIEW supports real-time control of mechatronic systems using hardware platforms such as NI CompactRIO or PXI controllers. Engineers can develop real-time control algorithms, implement closed-loop control strategies, and interface with sensors and actuators to control physical systems in real-time.

7.2 Hardware-in-the-Loop (HIL) Simulation: LabVIEW enables hardware-in-the-loop (HIL) simulation, allowing engineers to interface simulated mechatronic systems with physical hardware components. HIL simulation facilitates testing and validation of control algorithms, hardware interfaces, and system performance under realistic operating conditions, without the need for physical prototypes.

Section 8: Real-World Applications and Case Studies 8.1 Robotics and Automation: LabVIEW is widely used in robotics and automation applications for modeling, simulating, and controlling robotic systems, including manipulators, drones, and autonomous vehicles. Engineers use LabVIEW to develop motion control algorithms, sensor fusion techniques, and path planning strategies for robotic systems in industrial, research, and educational settings.

8.2 Automotive Systems: In the automotive industry, LabVIEW is employed for modeling and simulating mechatronic systems in vehicle dynamics, powertrain control, and driver assistance systems. Engineers use LabVIEW to simulate vehicle dynamics, optimize engine performance, and develop control algorithms for hybrid and electric vehicles, enhancing safety, efficiency, and reliability in automotive systems.

Section 9: Best Practices and Optimization Strategies 9.1 Model Validation and Verification: Before deploying mechatronic system models in real-world applications, engineers should validate and verify model accuracy against experimental data or physical prototypes. Model validation involves comparing simulation results with empirical data, performing sensitivity analysis, and calibrating model parameters to improve fidelity and predictive accuracy.

9.2 Optimization and Design Space Exploration: LabVIEW provides optimization tools for exploring design alternatives, optimizing system parameters, and identifying optimal solutions that meet design specifications and performance requirements. Engineers can use optimization algorithms, such as genetic algorithms or gradient-based methods, to search for optimal design configurations and control strategies in complex mechatronic systems.

Section 10: Future Trends and Developments 10.1 Model-Based Design: Model-based design approaches, integrating modeling, simulation, and control design, are becoming increasingly prevalent in mechatronic system development. LabVIEW continues to evolve as a platform for model-based design, offering enhanced simulation capabilities, model validation tools, and integration with other engineering tools and standards.

10.2 Cyber-Physical Systems: The emergence of cyber-physical systems (CPS) and the Internet of Things (IoT) presents new opportunities and challenges for mechatronic system modeling and simulation. LabVIEW is well-positioned to address the needs of CPS applications, enabling seamless integration of physical systems with digital control algorithms, cloud computing platforms, and edge devices for real-time monitoring and control.

Conclusion: Modeling and simulating mechatronic systems in LabVIEW offer engineers a powerful platform for exploring complex system interactions, optimizing design parameters, and accelerating product development cycles. By mastering the techniques and best practices outlined in this guide, engineers can leverage LabVIEW’s capabilities to design, simulate, and control innovative mechatronic systems in diverse application domains, from robotics and automation to automotive and aerospace engineering. With its intuitive interface, extensive libraries, and real-time capabilities, LabVIEW continues to be a valuable tool for engineers and researchers worldwide, driving advancements in mechatronics and interdisciplinary system integration.